- CN

- EN

ZONCN

AC Servo Drive,High Speed Servo Drive,Profinet Servo Drive,Servo Controller,Industrial Servo Drive,Modular Servo Drive,Servo Drive for Robotics,CNC Machine Servo Drive,Position Control Servo Drive,EtherCAT Servo Drive

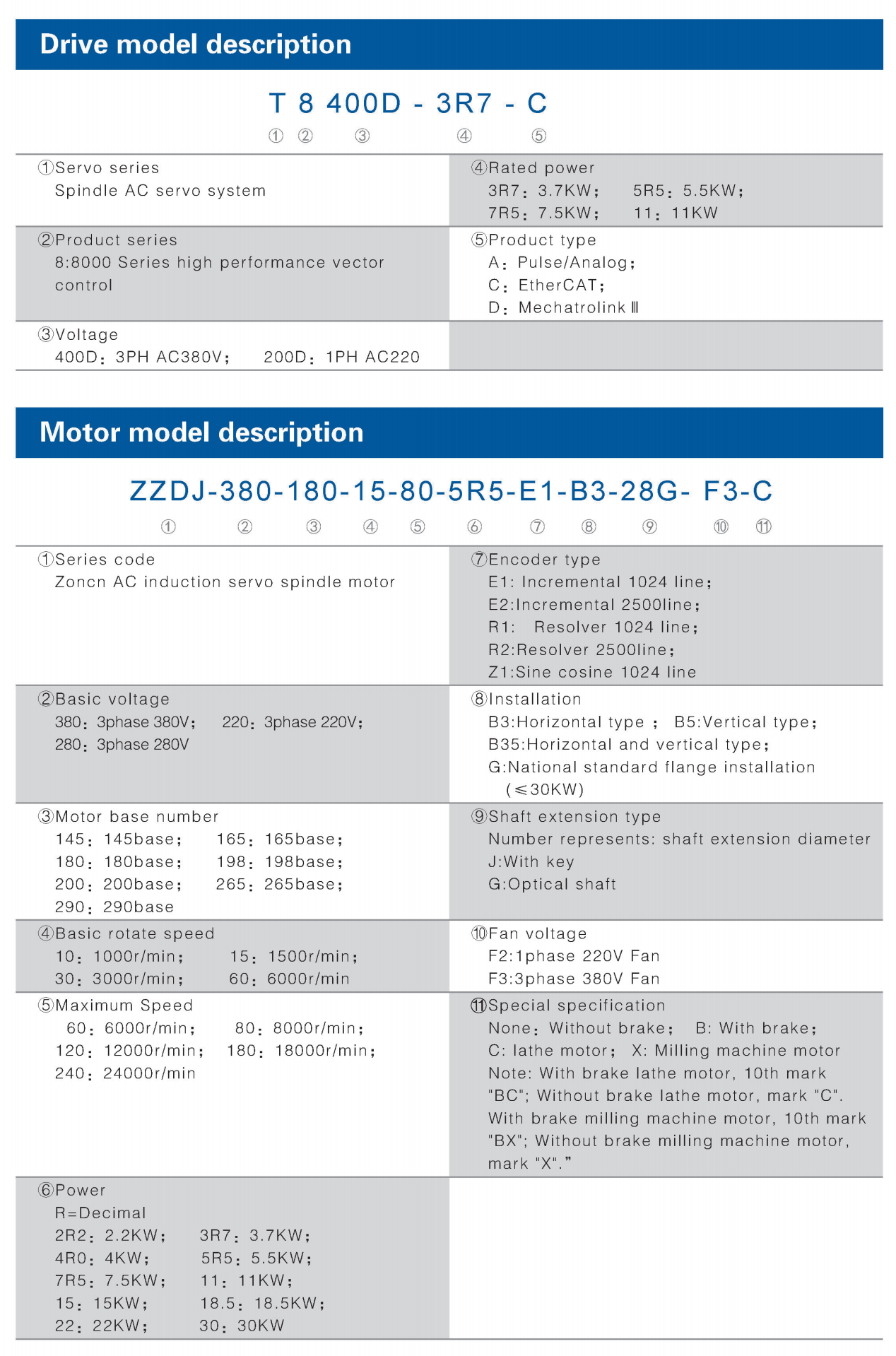

Item | T8000D |

Maximum frequency | Vector control:0~1000 V/F control:0~1500 |

Carrier frequency | 0.8kHz~16kHz The carrier frequency is automatically adjusted based on the load features. |

Input frequency resolution | Digital setting:0.01Hz Analog setting: Maximum frequencyx0.025% |

Control Mode | Sensorless flux vector control(SVC) Close-loop vector control (FVC) |

Start torque | G type:0.5Hz/150%(SVC); 0Hz/180%(FVC) |

Speed range | 1:100(SVC) 1:1000(FVC) |

Speed stability accuracy | ±0.5%(SVC) ±0.02%(FVC) |

Torque control accuracy | ±5%(FVC) |

Overload capacity | G type:60s for 150%of the rated current,3s for 180%of the rated current. |

Torque boost | Auto-boost; Customized boost:0.1%~30.0% |

V/F curve | Straight-line V/F curve Multi-point V/F curve N-power V/F curve(1.2-power,1.4-power,1.6-power,1.8-power,square) |

Ramp mode | Straight-line ramp. Four groups of acceleration/deceleration time with the range of 0.00'6500.0s |

DC braking | DC braking frequency:0.00Hz~Maximum frequency Braking time:0.0s~36.0s Braking action current value:0.0%~100.0% |

Auto voltage regulation(AVR) | It can keep constant output voltage automatically when the mains voltage changes |

Rapid current limit | It helps to avoid frequent over current faults of the AC drive. |

Support for kinds of PG cards | Differential input PG card; Rotating transformer PG card, Open-collector. |

Power dip ride through | The load feedback energy compensates the voltage reduction so that the AC drive can continue to run for a short time |

Overvoltage/overcurrent stall control | The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to over voltage/over current |

Torque limit and control | It can limit the torque automatically and prevent frequent over current tripping during the running process. Torque control can be implemented in the FVC mode. |

Onboard multiple preset speeds | It implements up to 16 speeds via the simple PLC function or combination of X terminal states |

Support motor type | Asynchronous motor, spindle asynchronous motor, Permanent Magnet Synchronous Motor, Spindle Synchronous Motor |

Model | Rated output power (kW) | Rated input current (A) | Rated output current (A) | Motor Power (kW) |

Input Voltage(V):3PHAC380V±15% | ||||

T8400D-0R75G | 0.75 | 3.8 | 2.5 | 0.75 |

T8400D-1R5G | 1.5 | 5 | 3.7 | 1.5 |

T8400D-2R2G | 2.2 | 5.8 | 5 | 2.2 |

T8400D-3R7G | 3.7 | 10 | 9 | 3.7 |

T8400D-5R5G | 5.5 | 15 | 13 | 5.5 |

T8400D-7R5G | 7.5 | 20 | 17 | 7.5 |

T8400D-11G | 11 | 26 | 25 | 11 |

T8400D-15G | 15 | 35 | 32 | 15 |

T8400D-18.5G | 18.5 | 38 | 37 | 18.5 |

T8400D-22G | 22 | 46 | 45 | 22 |

T8400D-30G | 30 | 62 | 60 | 30 |

T8400D-37G | 37 | 76 | 75 | 37 |

T8400D-45G | 45 | 92 | 90 | 45 |

T8400D-55G | 55 | 113 | 110 | 55 |

T8400D-75G | 75 | 157 | 150 | 75 |

T8400D-90G | 90 | 180 | 176 | 90 |

T8400D-110G | 110 | 214 | 210 | 110 |

T8400D-132G | 132 | 256 | 253 | 132 |

T8400D-160G | 160 | 307 | 300 | 160 |

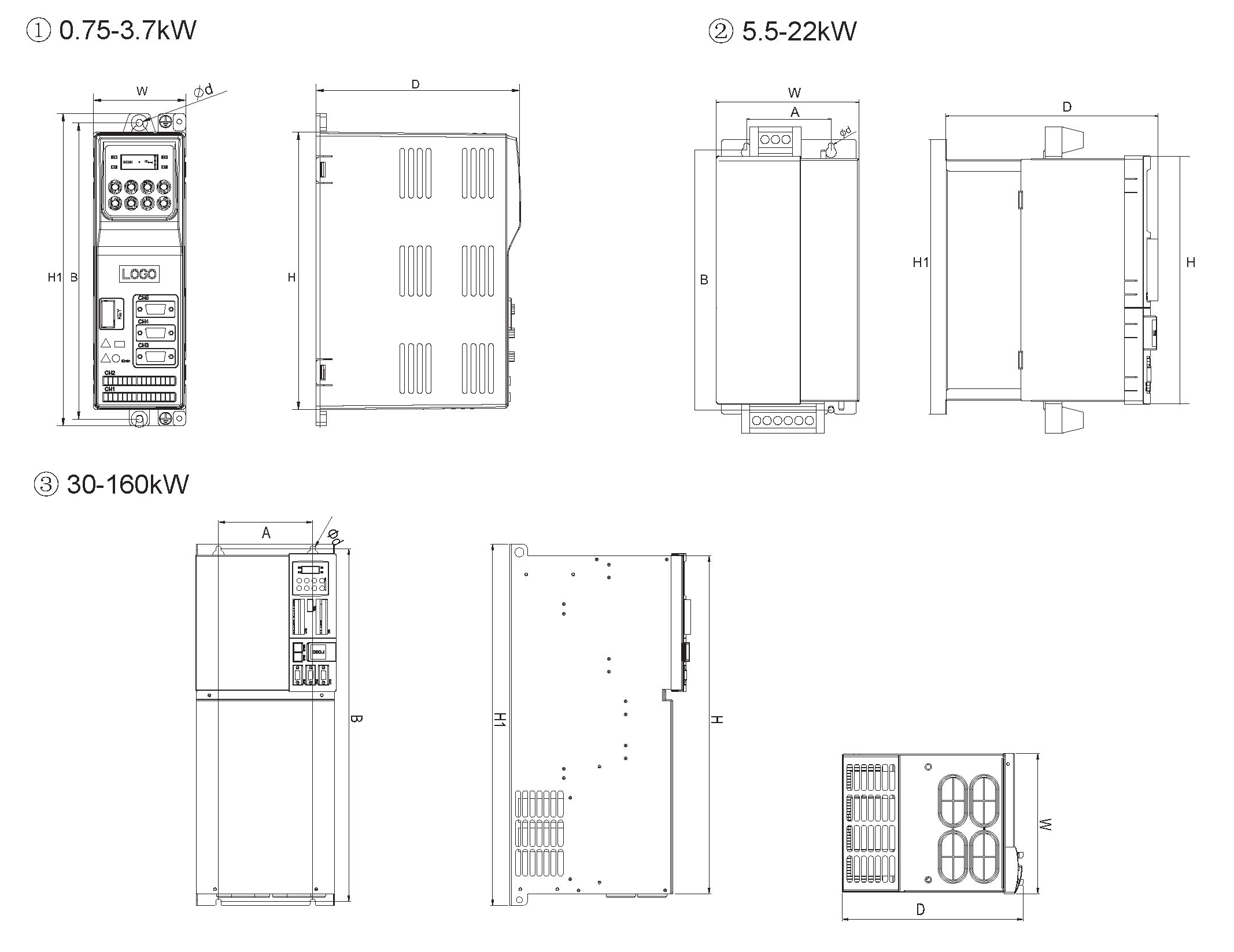

Model | Outline Dimension(mm) | Assembly Dimension(mm) | Install Method | |||||

W | H | H1 | D | A | B | Φd | ||

T8400D-0R75G | 74 | 222 | 250 | 163 | - | 237 | 5.5 | Wall mounting |

T8400D-1R5G | ||||||||

T8400D-2R2G | ||||||||

T8400D-3R7G-D | ||||||||

T8400D-3R7G | 89 | 235 | 260 | 200 | - | 250 | 5.5 | |

T8400D-5R5G | ||||||||

T8400D-7R5G | ||||||||

T8400D-11G | 136 | 235 | 260 | 202 | 80 | 250 | 5.5 | |

T8400D-15G | ||||||||

T8400D-18.5G | 193 | 235 | 260 | 222 | 132 | 250 | 5.5 | |

T8400D-22G | ||||||||

T8400D-30G | 177 | 439 | 475 | 256 | 120 | 460 | 7 | |

T8400D-37G | ||||||||

T8400D-45G | 235 | 575 | 615 | 308 | 160 | 600 | 9 | |

T8400D-55G | ||||||||

T8400D-75G | 275 | 595 | 630 | 340 | 200 | 612 | 9 | |

T8400D-90G | ||||||||

T8400D-110G | ||||||||

T8400D-132G | 304 | 844 | 880 | 451 | 200 | 838 | 11 | |

T8400D-160G | ||||||||