- CN

- EN

ZONCN

High Voltage Variable Frequency Drive, HV VFD, Medium Voltage Variable Frequency Drive, MV VFD, Medium Voltage Inverter, MV Inverter, High Voltage Inverter, HV Inverter, Medium Voltage Variable Frequency Drive, Medium Voltage AC Drive, High Voltage AC Drive, Medium Voltage Variable Speed Drive, MV VSD, High Voltage Variable Speed Drive, HV VSD, Medium Voltage Frequency Converter, High Voltage Frequency Converter, High Power Inverter

GH Series Medium and High Voltage VFD

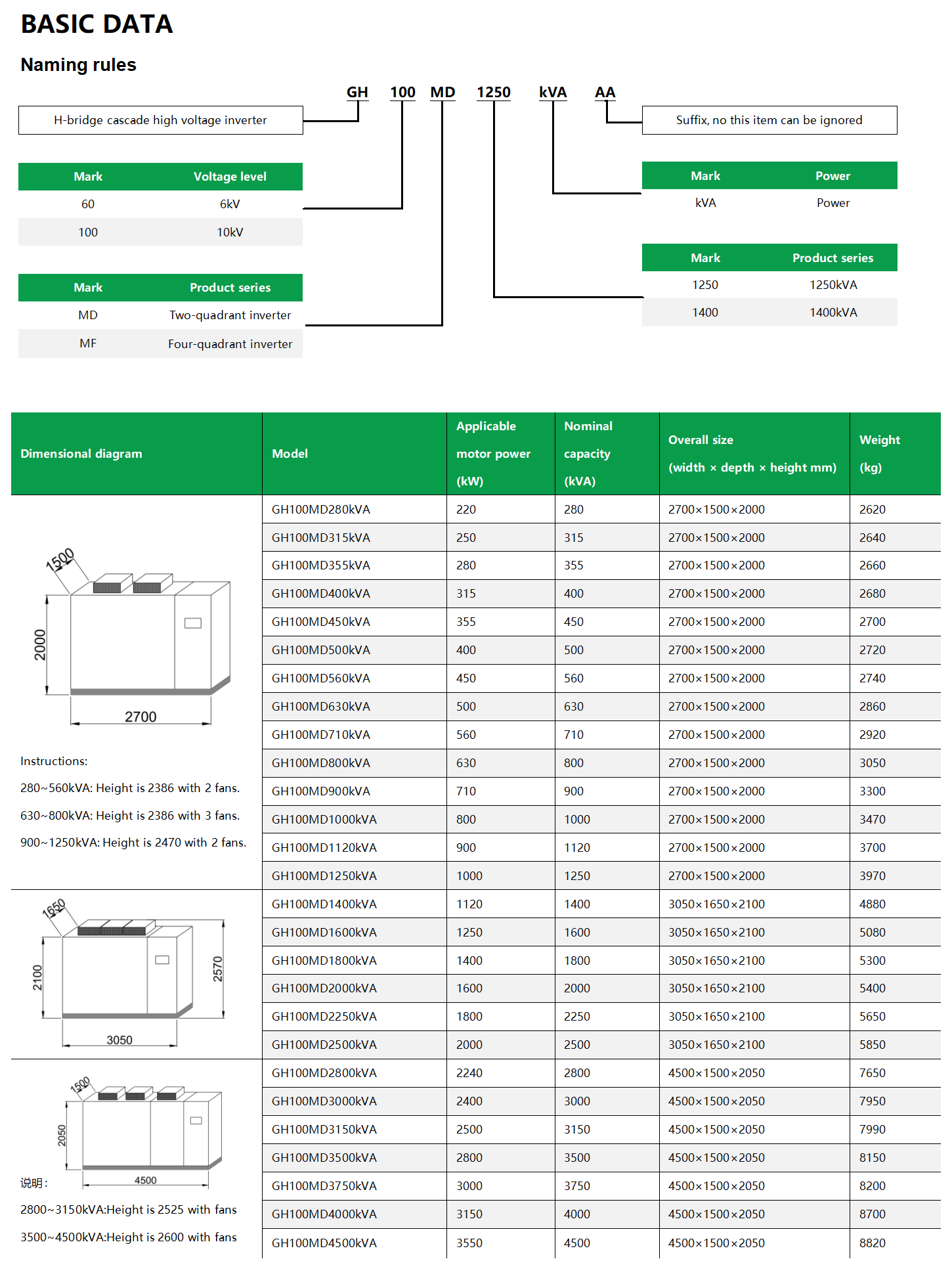

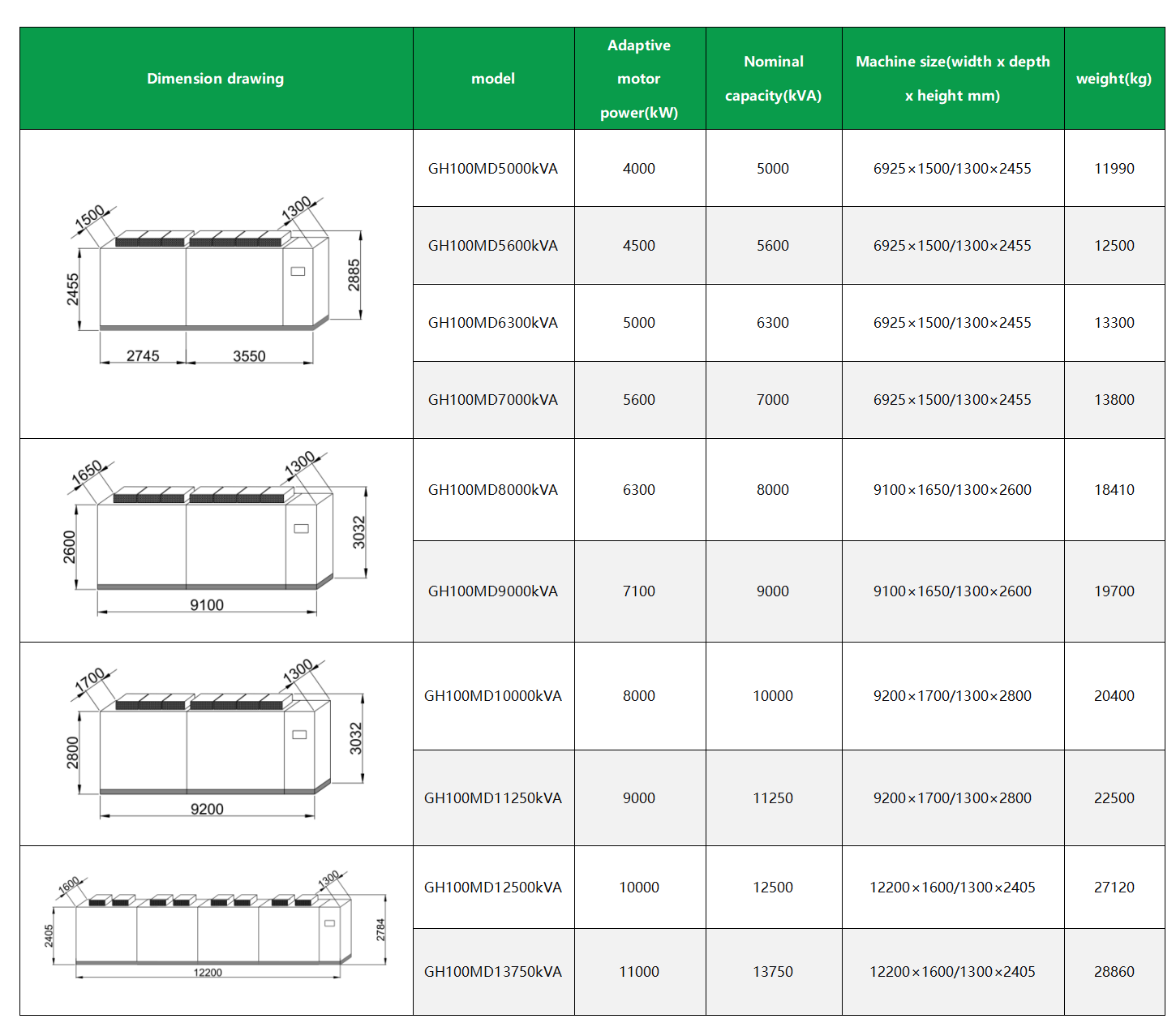

■ Remarks

■ The above dimensions and weights are for reference only. The specific dimensions and weights shall be subject to the technical agreement.

■ The input voltage and output voltage of the standard series are consistent.

■ The height of the overall dimensions does not include the height of the fans, and the fan height needs to be additionally added by 300mm to 600mm.

■ The above overall dimensions and weights refer to the sum of the control cabinet, unit cabinet, and transformer cabinet, excluding the power frequency bypass cabinet part.

■ The distance from the front of the equipment to the wall shall not be less than 1500mm, the distance from the back to the wall shall not be less than 1000mm, the distance from the side to the wall shall not be less than 800mm, and the distance from the top to the roof shall not be less than 1000mm.

■ The standard overload capacity is 110% for 1 minute, allowing overload for 1 minute every 10 minutes. Overload capacities of 125%, 150%, and 200% can be selected to meet different application needs.

■ The applicable motor power may vary due to differences in motor types and structures, and is for reference only.

Common | Electricity: induced draft fan, primary/secondary fan, circulating water pump, feed water pump, condensate pump, slurry circulating pump, vertical coal mill |

Oil, gas and chemical industry: electric submersible pumps, water injection pumps, oil transfer pumps, pipeline compressors, LNG compressors, air separation compressors, syn gas compressors, ammonia compressors (ice machines)product gas compressors, propylene compressors, carbon dioxide compressor | |

Mining: belt conveyors, main fans, gas discharge pumps, mud pumps, crushers, semi-autogenous grinding, ball mills, high-pressure grinding mills | |

Cement: raw mill circulating fan, coal mill exhaust fan, cement mill exhaust fan, kiln head exhaust fan, kiln tail high temperature fan kiln tail exhaust fan, running cooling fan, coal mill, roller press | |

Metallurgy: dust removal fans, sintering main exhaust fans, blast furnace blowers, circulating water pumps, phosphorus removal pumps, slag washing pumps, air separation compressors, mills, stamping machines, two-way energy recovery compressors | |

Municipal: water intake pump, water supply pump, primary water pump, secondary clean water pump, desalination pump, booster pump, irrigation pump | |

Waste-to-energy: various types of ordinary fans and water pumps | |

The main | Low voltage ride through, self-start after power failure recovery(within 20s),unit bypass function, on-the-fly start function, synchronous switching function, control power supply redundancy design (optional), power unit redundancy design(N+1,optional)), fan redundancy(optional) and other functions customized according to customer needs, mill-specific control function modules |

MV VFD Supporting | Excitation inrush current suppression cabinet, one-to-one manual bypass cabinet, one-to-two manual bypass cabinet, one-to-one automatic bypass cabinet, one-to-two automatic bypass cabinet, one-to-one synchronous switching cabinet, output reactor cabinet, Isolation cabinet |

Project | Voltage | 6kV Series | 10kV Series |

Input | Input rated voltage | 3-phase 50/60Hz, 6kV | 3-phase 50/60Hz, 10kV |

Voltage fluctuation range | 6kV/10kV±10% full load operation, -10%~35% allows long-term derating operation | ||

Frequency range | 50Hz±10% | ||

Unit input voltage | 690V | ||

Input power factor | >0.95(20% load or more) | ||

Input current harmonics | <2% meets IEEE519-1992 and GBT14549-93 | ||

Output | Output voltage range | 0~6kV | 0~10kV |

Output capacity range | 230~7000kVA | 250~12500kVA | |

Unit output voltage | 690V | ||

Output frequency range | 0~50Hz max330Hz 120Hz and above factory customized | ||

Speed ratio | 40:1(Universal Vector)100:1(SVC)200:1(FVC) | ||

Speed accuracy | ±0.5%(SVC) ±0.2%(FVC) | ||

Torque response | >750rad/s | ||

Starting torque | 0.5HZ/150%(SVC); OHz/180%(FVC) | ||

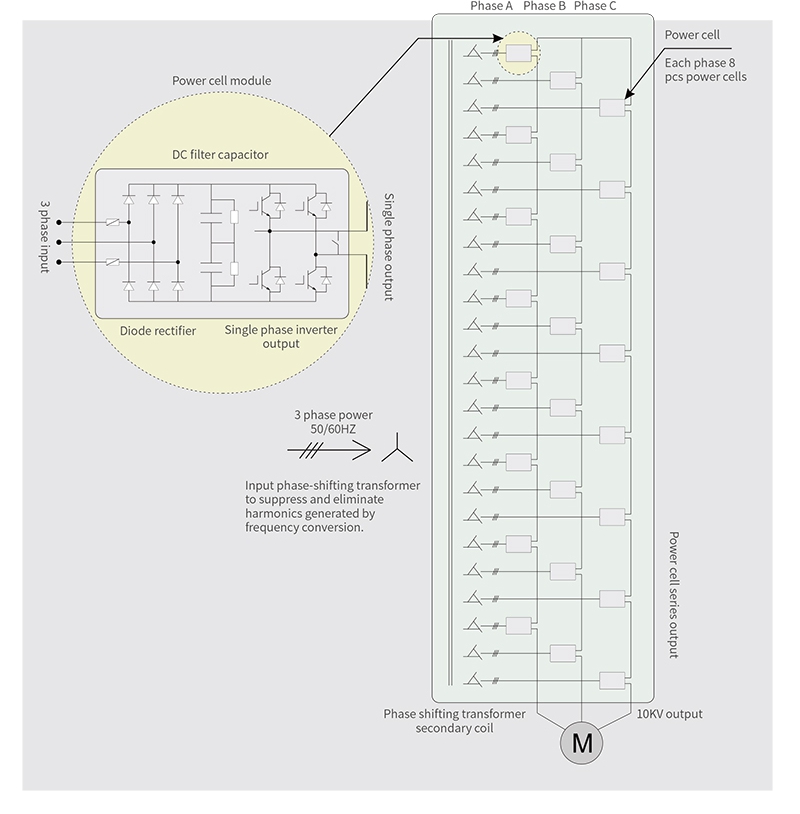

Technical Solution | Unit cascade, AC-DC-AC, high-high mode | ||

Control method | General vector, speed sensorless/sensorless control (SVC/FVC) | ||

Rectification form | Diode three-phase full bridge | ||

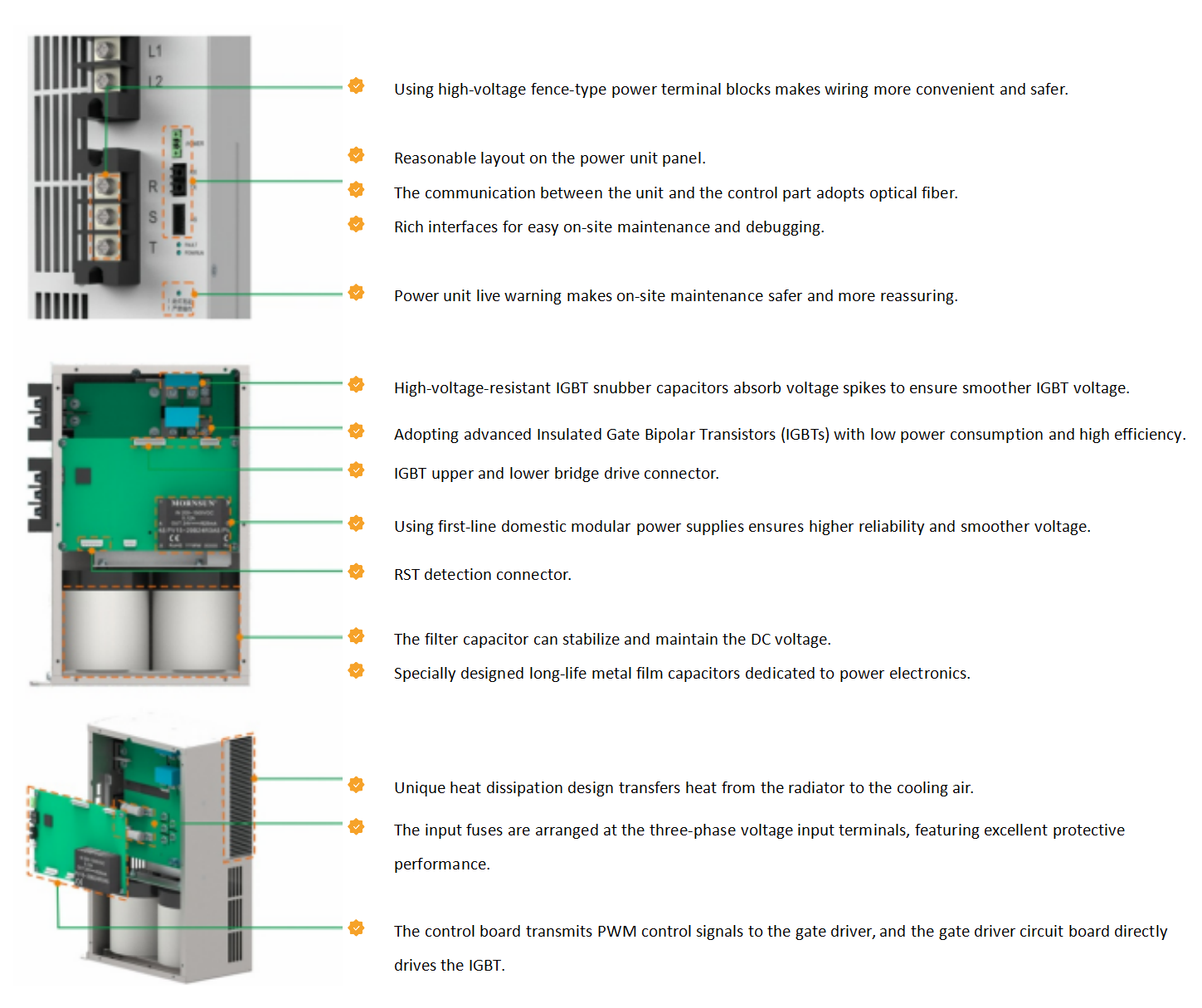

Inverter form | IGBT inverter bridge | ||

Acceleration and deceleration time | 0.1-6500 seconds, >6500 seconds can be customized by the manufacturer | ||

Start-Stop Control | Local or remote | ||

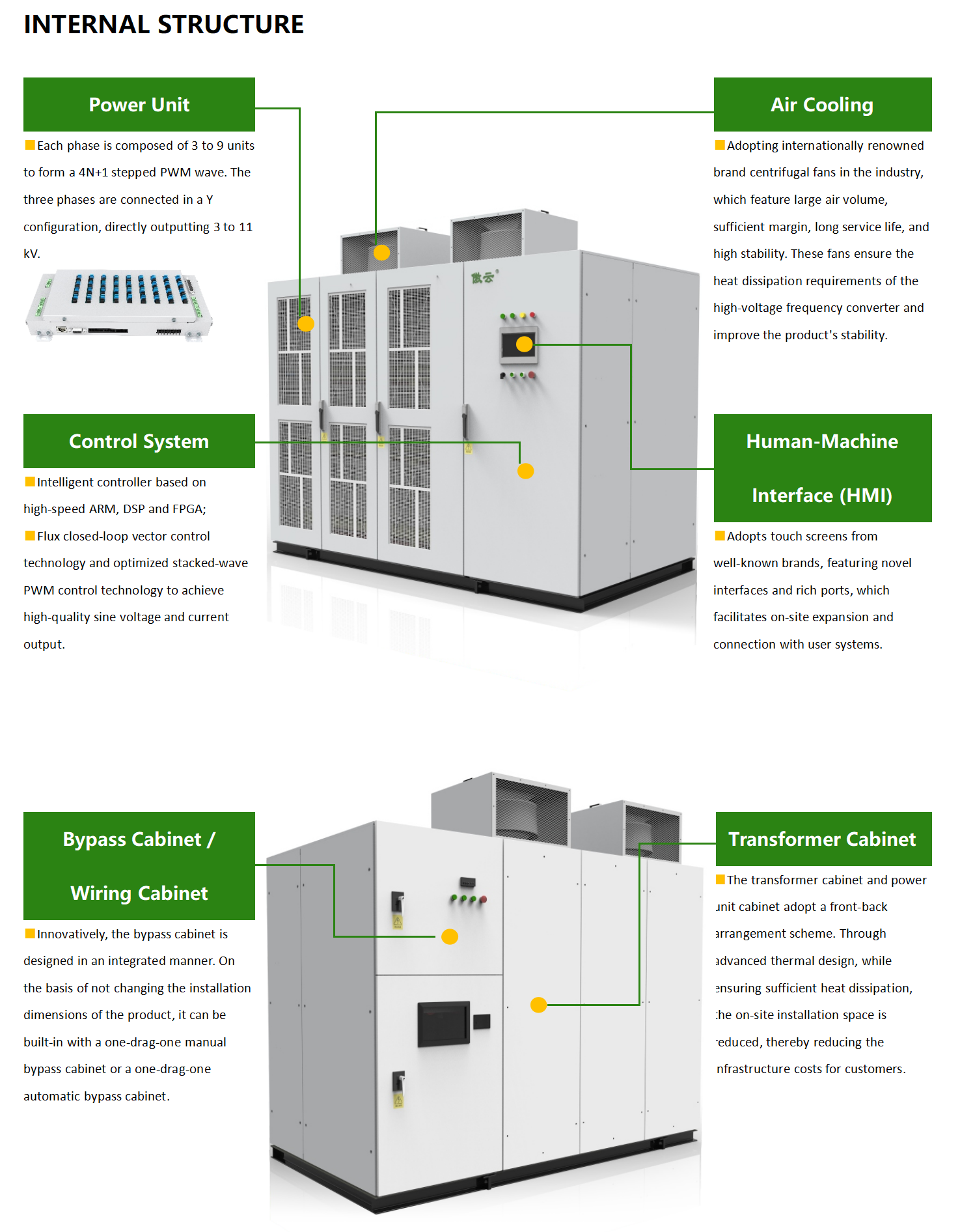

Control System | ARM, DSP, FPGA, CPLDSHMI | ||

Panel Display | Touch screen/LCD optional, Simplified Chinese | ||

Overload capacity | 120% rated current, 1 minute | ||

Overall efficiency | >96% | ||

Is there a fuse in the frequency converter? | Power unit input side with fuse | ||

Is optical fiber used in the electrical isolation part? | yes | ||

Is an input filter required? | no | ||

Is an output filter required? | no | ||

Is power factor compensation required? | no | ||

Power unit protection | Overvoltage, undervoltage, voltage balancing, input phase loss, overcurrent, overtemperature, communication, etc. | ||

System protection | Motor overload, output overload, output short circuit, output grounding, input overcurrent, input overvoltage, input unbalance, input grounding, cooling fan fault alarm, door switch Interlock protection, transformer overheat alarm, transformer overheat trip, etc. | ||

Mean time between failures | 50,000 hours | ||

Communication interface | CANbus, Modbus, PROFIBUS can be customized according to users | ||

Switch input | 10-way, half/full width relay dry contact | ||

Switching output | 16-way, relay dry contact | ||

Analog input | 4 channels, 4~20mA or 0~10V | ||

Analog output | channels, 4~20mA or 0~10V | ||

Usage Environment | indoor | ||

Ambient temperature | -10℃~+40℃, +40℃~+50℃ derating operation; low T-10℃, preheating is required before starting | ||

Ambient humidity | 5%~95%, no condensation | ||

Altitude | <1000m, more than 1000m need to reduce the rating, please specify when ordering | ||

Total equipment noise | <75dB | ||

Cooling method | Forced air cooling | ||

Protection level | IP30 | ||

Cabinet type | GGD combination type | ||

Inlet and outlet line | Bottom in and bottom out / top in and top out Special can be customized according to users | ||

Control power supply | 380V±10%AC three-phase four-wire | ||

Design features |

| User Benefits |

High reliability, adopting 1700V high-voltage IGBT (Insulated Gate Bipolar Transistor) from well-known brands. |

| Ensure highly reliable operation with an average time between failures (MTBF) of 12 years. |

The main circuit uses long-life self-healing metal film capacitors to replace traditional electrolytic capacitors that need to be replaced regularly. |

| Low maintenance and operation costs, requiring no maintenance or replacement throughout the full life cycle of the frequency converter. |

The overall system efficiency reaches up to 97.5% (design value). |

| Especially in the field of flow control applications, the energy-saving effect is quite remarkable. |

Diode rectification ensures that the power factor reaches more than 95% within the speed regulation range. |

| No power factor compensation capacitors need to be set. |

Multi-level PWM control mode makes the output waveform very similar to a sine wave (11 levels for 6kV frequency conversion, and □ levels for 10kV frequency conversion). |

| The waveform close to a perfect sine wave allows the motor to operate without derating, and the motor has no additional harmonic heating. |

Adopting multi-pulse rectification and phase-shifting transformers: 3.3kV class: 18 pulses; 6.0kV class: 30 pulses; 10kV class: 48 pulses. |

| No harmonic filter is required, meeting the high-order harmonic current output limit standards specified in IEEE-519 (1992) and GB14549-1993. |

Even if the power supply voltage drops instantaneously or there is a power outage within 300 milliseconds, the frequency converter can maintain output and continue to operate. |

| For important loads, it provides safe protection. |

The synchronous switching function enables smooth and ripple-free switching to the power frequency bypass. |

| One frequency converter can control multiple motors. When switching the power supply of the motor from variable frequency to power frequency bypass, there is no impact on the power grid and the motor, and it can be used for the soft start of extra-large power motors without disturbance. |

Perfect control ensures short acceleration time and excellent dynamic response. |

| It can meet the requirements of high-precision control. For variable torque loads, it has the protection functions of preventing overcurrent during acceleration and overvoltage during deceleration. |

The frequency converter features an integrated design with a built-in input dry-type isolation transformer. |

| It provides better protection for the motor, simplifies installation, and has low installation costs. |

Directly drive ordinary high-voltage motors. It can be adapted to standard synchronous/asynchronous motors and other special motors. |

| No transformer is required, saving costs and energy, while also reducing the requirements for installation sites. |

The main circuit of the GH series is composed of an input transformer and several single-phase PWM frequency conversion units. For 6kV, 5 frequency conversion units per phase can generate an 11-level output voltage. For 10kV, 8 frequency conversion units per phase can generate a 17-level output voltage. The pre-charging circuit can reduce the capacitor charging current and transformer magnetizing inrush current when applying high voltage, reduce the impact on the power grid, protect the frequency converter, and extend the service life of the frequency converter.