- CN

- EN

#CASES ·2025-08-27

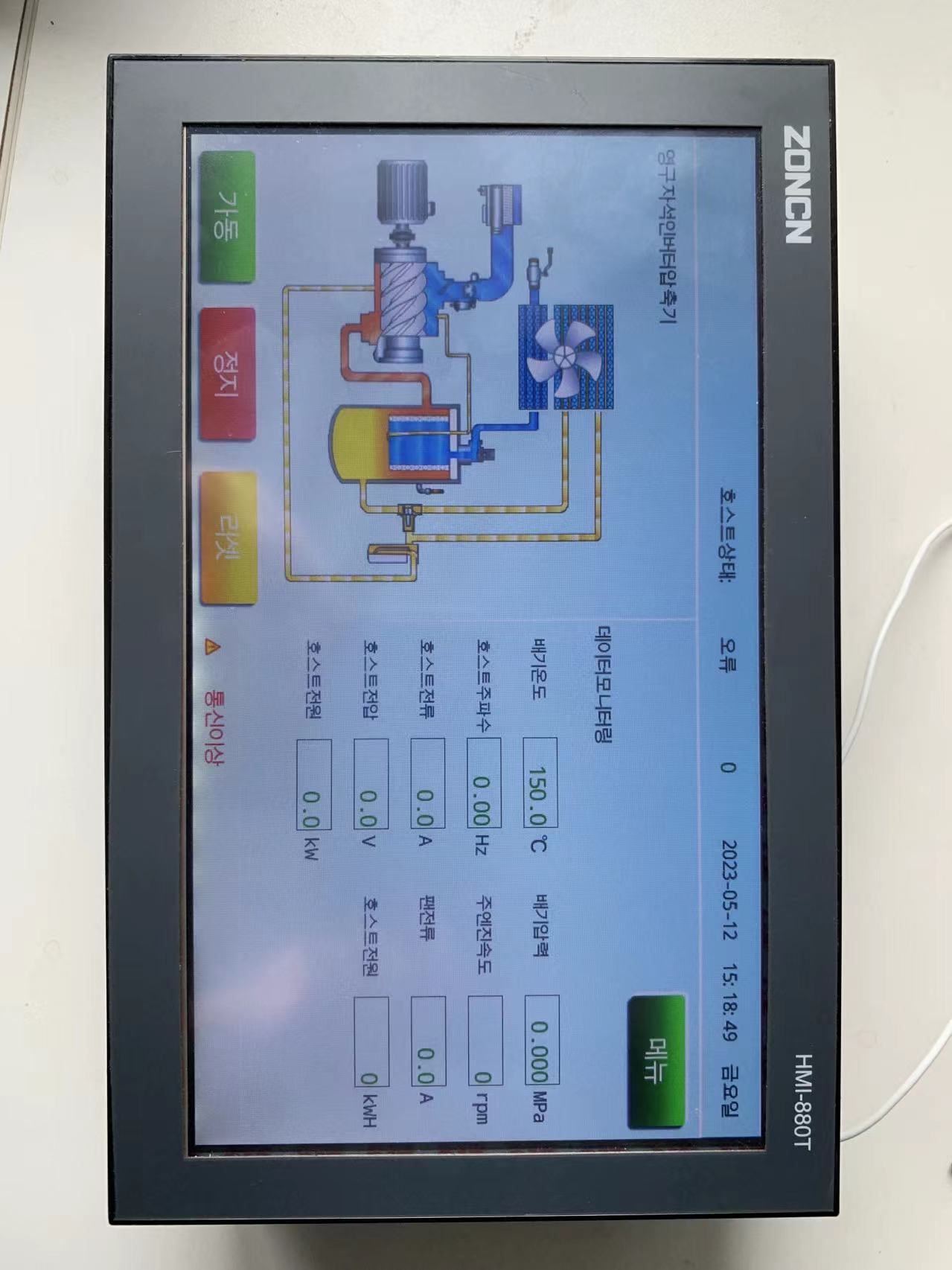

Case Study: Streamlined Procurement of Screw Compressors for South Korean Industrial Client

Client: Air Compressor Academy , a major South Korean Air Compressor Distributor, sought energy-efficient screw compressors compliant with KCs Safety Standards.

Challenges:

1. Regulatory Hurdles: Mandatory KCs Safety Certification (electromagnetic compatibility, noise levels ≤75 dB).

2. Technical Requirements: Operation in dusty environments with 24/7 uptime reliability.

3. Localization Needs: 40% local content compliance under South Korea’s Foreign Investment Promotion Act.

Solutions by Industrial Sourcing:

1. Certified Supplier Network: Shortlisted Jiangsu Hankesen (HKS series) and Ma’anshan Jufeng(JF series) for KC compliance.

2. Custom Engineering:

· Upgraded HMI Controller with Korean Language.

· Integrated IoT sensors for real-time vibration monitoring, reducing maintenance costs by 30%.

3. Localized Production: Partnered with Dongkuk Steel for 40% localized component sourcing (e.g., stainless steel casings), meeting trade incentives .

4. Logistics Optimization: Consolidated shipments via Busan Port’s green energy terminal, cutting transit time to Incheon port from 10 to 14 days.

Results:

· Cost Efficiency: Landed cost reduced by 18% through bulk tariffs and VAT exemptions.

· Performance: Achieved 30% energy saving in end user trials.

· Compliance: Full KC certification secured within 6 months.

Value-Adds:

· Risk Mitigation: Zero-defect liability +

· 24/7 bilingual support: Korean/English technical translation.

· After-sales: Extended warranties and discounted spare parts.

Conclusion: Strategic supplier partnerships, technical customization, and agile logistics

2023-01-09

2023-01-09

2023-01-09